Auto Parts Manufacturing

Introduction

At its core lies the critical process of auto parts manufacturing, which serves as the foundation for every vehicle’s functionality, safety, and performance. Whether it’s the tiniest sensor or the engine block itself, precision manufacturing is what brings design concepts to life.

This article explores the intricate world of auto parts production, examining technologies, materials, processes, trends, and challenges shaping this essential industry.

What Is Auto Parts Manufacturing?

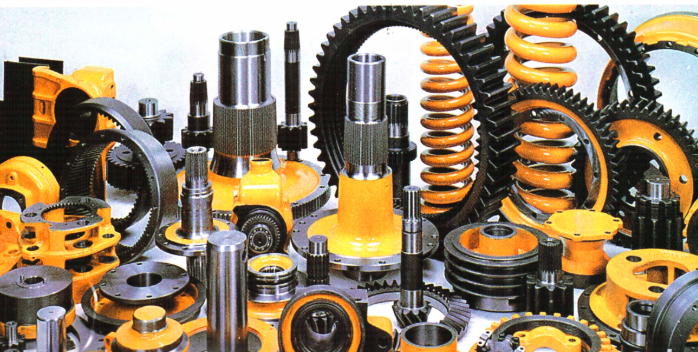

Auto parts manufacturing refers to the industrial process of designing, fabricating, and assembling components that go into vehicles. These parts can be mechanical, electronic, or structural in nature and are produced using a combination of advanced machinery, skilled labor, and quality control systems.

From chassis frames and transmission gears to infotainment systems and brake pads, the scope of auto parts is enormous. Manufacturers may produce components either for original equipment manufacturers (OEMs) or for the aftermarket.

Categories of Auto Parts

There are hundreds of individual components in a vehicle, but they are broadly classified into the following categories:

- Engine Components: Pistons, cylinder heads, crankshafts.

- Drivetrain Parts: Transmission assemblies, differentials, axles.

- Chassis Systems: Frames, suspensions, steering columns.

- Electrical and Electronics: Sensors, battery systems, ECU units.

- Interior and Exterior Trim: Dashboards, seats, bumpers, grilles.

- Braking Systems: Brake pads, rotors, calipers, brake lines.

Each part demands a specific manufacturing technique based on its function, material, and required durability.

Materials Used in Auto Manufacturing

Material selection is critical in determining a component’s weight, strength, corrosion resistance, and cost. Common materials include:

- Steel: Predominantly used for structural and load-bearing parts.

- Aluminum: Lightweight and corrosion-resistant; used in engine and body components.

- Plastics: Extensively used for dashboards, connectors, and housings.

- Rubber: Found in tires, gaskets, and suspension bushings.

- Composites: Emerging in high-performance and electric vehicles due to their strength-to-weight ratio.

Materials often undergo extensive treatment to enhance mechanical properties before and after manufacturing.

Manufacturing Processes

1. Casting

Used for complex parts like engine blocks.

2. Forging

High-strength components such as crankshafts and connecting rods are shaped under extreme pressure.

3. Stamping

Sheet metals are pressed into shape using dies. Common in the production of body panels.

4. Machining

Includes milling, drilling, turning, and grinding to achieve tight tolerances for parts like gears and spindles.

5. Injection Molding

Used for plastic components. Molten plastic is injected into a mold and solidified.

Precision and Tolerance

Modern vehicles demand incredibly precise components. Even a deviation of a few micrometers can lead to inefficiency or failure. That’s why manufacturers implement strict tolerance guidelines, especially for parts like engine valves, fuel injectors, or brake systems.

To maintain quality, companies use:

- Computer-Aided Design (CAD)

- Computer-Aided Manufacturing (CAM)

- Coordinate Measuring Machines (CMM)

- In-line Quality Inspection Tools

Quality assurance is not optional—it’s embedded into every step of production.

OEM vs Aftermarket Manufacturing

Auto parts manufacturers typically serve two markets:

OEM (Original Equipment Manufacturer)

These suppliers produce parts that are used by automobile brands during vehicle assembly. OEM parts follow strict brand specifications and often require specific certifications.

Aftermarket

While many are high-quality, the industry also faces challenges with counterfeit or substandard products.

Leading auto parts brands often operate in both sectors to meet market demand while ensuring compatibility and reliability.

Automation in Manufacturing

Automation is revolutionizing auto parts manufacturing From robotic arms on assembly lines to AI-powered quality checks, the industry is moving toward a smart factory environment.

See also: Environmental Consulting Services for Sustainable Business Practices

Benefits of automation include:

- Increased Productivity: Machines can operate 24/7 with minimal downtime.

- Consistent Quality: Reduces human error.

- Cost Efficiency: Lowers labor costs over time.

- Real-Time Monitoring: Sensors and software allow predictive maintenance.

Factories are also integrating Industry 4.0 tools such as cloud computing, IoT, and machine learning for better data analysis and decision-making.

Challenges in Auto Parts Manufacturing

Despite advancements, the industry faces ongoing challenges:

- Supply Chain Disruptions: Global events, raw material shortages, and logistic delays can halt production.

- Labor Shortage: Skilled machinists and engineers are in high demand.

- Stringent Regulations: Emissions, safety, and quality standards vary across regions.

- Cost Pressures: OEMs often push for lower prices, affecting supplier margins.

To remain competitive, companies must invest in R&D, diversify suppliers, and maintain agile operations.

Trends Shaping the Future

1. Electric Vehicles (EVs)

The shift to electric cars is driving demand for new components like battery packs, electric motors, and lightweight materials.

3. Digital Twins

Virtual models of parts and processes enable real-time simulation and optimization.

4. Global Expansion

Many companies are setting up factories in emerging markets to reduce costs and meet local demand.

Selecting a Manufacturing Partner

For businesses in need of auto parts manufacturing, choosing the right partner is crucial. Here’s what to consider:

- Experience in Automotive Standards

- Technical Capabilities and Machinery

- Certifications (ISO, IATF 16949)

- Scalability and Flexibility

- Reputation and Client Reviews

- Location and Supply Chain Efficiency

A reliable manufacturer ensures quality, timely delivery, and compliance with regulations.

Conclusion

Auto parts manufacturing is a cornerstone of the automotive industry, playing a pivotal role in vehicle safety, functionality, and innovation. With evolving technologies, stricter standards, and global competition, manufacturers must continuously adapt to meet industry needs.

From material selection to advanced machining and automation, every stage of the manufacturing process must be optimized for precision and efficiency. As electric and autonomous vehicles redefine transportation, the demand for intelligent, lightweight, and sustainable parts will only grow—making this sector more vital than ever.